Manufacturing facilities in Pittsburgh face unique security challenges that require sophisticated video surveillance solutions. From protecting valuable inventory and equipment to monitoring multiple production areas around the clock, today’s industrial operations demand surveillance systems that go far beyond basic security cameras.

The right video surveillance Pittsburgh system can transform how you protect your manufacturing facility, providing real-time monitoring, advanced threat detection, and seamless integration with your existing security infrastructure. Let’s explore the essential features that make surveillance systems truly effective for Pittsburgh’s manufacturing sector.

Modern manufacturing operates on tight schedules, often running multiple shifts or even continuous production cycles. This reality makes round-the-clock surveillance monitoring absolutely critical for facility security.

Professional monitoring services provide trained security personnel who actively watch your facility through remote CCTV surveillance systems. These operators can identify potential security threats in real-time and immediately dispatch on-site security personnel when needed. This proactive approach means threats are addressed before they become major security incidents.

The difference between passive recording and active monitoring becomes clear during off-hours when your facility is most vulnerable. While traditional systems simply record footage for later review, active monitoring provides immediate response capabilities that can prevent theft, vandalism, and unauthorized access as incidents occur.

For Pittsburgh manufacturing facilities, this level of monitoring coverage ensures your valuable equipment, raw materials, and finished products remain protected even when your regular staff isn’t on-site.

Effective video surveillance Pittsburgh systems require careful planning of camera locations to ensure comprehensive facility protection. Manufacturing environments present unique challenges due to their size, complexity, and the variety of areas that require monitoring.

Entrances and exits represent the most critical monitoring points for any facility. Installing CCTV cameras at all vehicle gates, pedestrian entrances, loading docks, and emergency exits provides complete perimeter control. This placement strategy helps track everyone entering and leaving your facility while creating detailed records of all access activity.

Inventory storage areas deserve special attention in camera placement planning. Whether you’re storing raw materials, work-in-progress items, or finished goods, these areas often contain your facility’s most valuable assets. Strategically positioned cameras can monitor inventory movement, detect unauthorized access, and provide evidence if theft occurs.

Production floor monitoring presents additional considerations for camera placement. While respecting employee privacy, surveillance systems can monitor equipment operation, track workflow efficiency, and identify safety incidents before they escalate into serious problems.

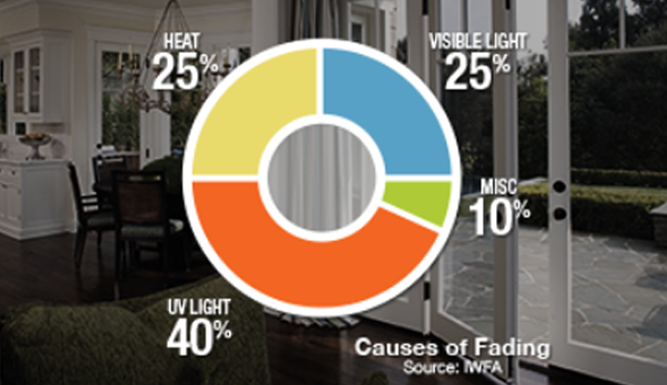

Manufacturing facilities operate in challenging conditions that can limit the effectiveness of standard security cameras. Dust, steam, variable lighting conditions, and extreme temperatures all impact traditional video surveillance equipment.

Thermal imaging cameras represent a significant advancement for industrial surveillance applications. These specialized cameras detect heat signatures rather than relying on visible light, making them highly effective in darkness, shadows, steam, and adverse weather conditions common in manufacturing environments.

The technology proves particularly valuable for monitoring outdoor storage areas, perimeter fencing, and areas where lighting conditions change frequently throughout production cycles. Thermal cameras can detect intruders even when they’re hidden behind obstacles or operating in complete darkness.

High-definition cameras with low-light capabilities provide another essential technology for manufacturing surveillance. These cameras maintain image quality in varying lighting conditions, ensuring clear footage whether monitoring well-lit production areas or dimly lit storage zones.

Modern manufacturing facilities require surveillance systems that integrate seamlessly with existing security infrastructure while providing room for future expansion. The best video surveillance Pittsburgh solutions work as part of comprehensive security ecosystems rather than standalone systems.

Access control integration represents one of the most valuable features for manufacturing facilities. When surveillance cameras work together with keycard systems, biometric readers, and door controls, facility managers gain complete visibility into who accesses specific areas and when. This integration helps maintain security protocols while creating detailed audit trails for compliance purposes.

Motion detection capabilities add another layer of automated security monitoring. Advanced systems can distinguish between authorized personnel movement and potential security threats, reducing false alarms while ensuring legitimate concerns receive immediate attention.

For large manufacturing facilities, scalability becomes crucial as operations grow and change. Professional surveillance systems can support integration of hundreds or even thousands of cameras across multiple buildings and outdoor areas. This scalability ensures your security investment continues providing value as your facility expands.

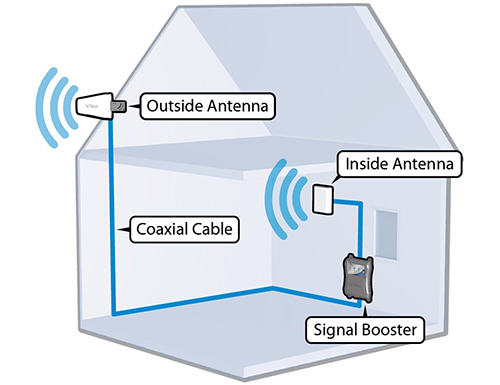

Today’s manufacturing operations require security systems that provide instant access to surveillance footage from any location. Cloud-based surveillance platforms enable facility managers, security personnel, and authorized staff to monitor operations remotely using smartphones, tablets, or computers.

Wi-Fi enabled systems with cloud storage capabilities ensure surveillance footage remains accessible even if on-site equipment experiences problems. This redundancy protects against data loss while providing the flexibility to review footage from multiple locations.

Push notification systems add immediate awareness of security events. When cameras detect motion, unauthorized access, or other programmed triggers, designated personnel receive instant alerts allowing for rapid response to potential threats.

The ability to access live and recorded footage remotely proves especially valuable for multi-shift operations. Managers can review previous shift activities, monitor current operations, and ensure security protocols are being followed without being physically present at the facility.

The complexity of manufacturing facility surveillance requires professional installation and ongoing technical support. While the technology continues advancing rapidly, the success of any system depends on proper configuration, integration, and maintenance.

Working with experienced video surveillance Pittsburgh professionals ensures your system design meets your facility’s specific needs. Professional installers understand the unique challenges of manufacturing environments, including electrical interference, environmental conditions, and workflow considerations that impact camera placement and system configuration.

At TN Security Pittsburgh, we specialize in comprehensive surveillance solutions for manufacturing facilities throughout the region. Our team understands the unique security challenges facing Pittsburgh’s industrial sector, from steel production to advanced manufacturing operations. We provide complete system design, professional installation, and ongoing support to ensure your surveillance system continues protecting your facility effectively.

Manufacturing facilities often operate under strict regulatory requirements that impact security system specifications. Different industries have specific documentation, access control, and monitoring requirements that surveillance systems must support.

Video management systems designed for industrial applications provide the detailed reporting and documentation capabilities necessary for regulatory compliance. These systems can generate access reports, incident documentation, and audit trails that meet industry-specific requirements.

The ability to search and export specific footage segments becomes crucial for incident investigation and regulatory reporting. Professional surveillance systems provide tools for quickly locating relevant footage and creating documentation packages that meet legal and compliance standards.

Selecting the right surveillance system for your manufacturing facility requires working with security professionals who understand both the technology and the unique challenges of industrial operations. The investment in professional video surveillance Pittsburgh services provides long-term value through improved security, operational efficiency, and regulatory compliance.

When evaluating surveillance providers, consider their experience with manufacturing facilities, their ability to integrate with existing systems, and their commitment to ongoing support and maintenance. The right partner will work with you to design a system that meets your current needs while providing flexibility for future expansion and technology updates.

For manufacturing facilities in Pittsburgh looking to upgrade or implement comprehensive video surveillance systems, TN Security Pittsburgh offers the expertise and technology solutions necessary for effective facility protection. Contact us at 412-967-0467 to discuss your specific surveillance requirements, or visit our facility at 3287 Library Road, Pittsburgh, PA 15234. You can also reach our team at sales@teamnutztechnology.com to schedule a comprehensive security assessment for your manufacturing operation.

The right video surveillance system transforms facility security from reactive to proactive, providing the visibility, control, and documentation necessary for modern manufacturing operations. With proper planning, professional installation, and ongoing support, your surveillance investment will continue protecting your facility, personnel, and assets for years to come.